|

|

Kitfox™

SERVICE LETTER #25

March

12, 1993

SUBJECT:

Lift Strut Attachment

TO:

Kitfox™ Owners, All Models

FROM:

SkyStar Aircraft Corporation

Recent

experience with creation of the Kitfox™ XL manual has allowed us

to rethink the way we answer two commonly asked questions:

1.

How do I make sure my dihedral is set correctly?

2.

What should I do if I find a need to force (lift with

pressure) the forward or aft lift strut, to make

DIHEDRAL

The

first question, regarding dihedral, is easy to answer through the

use of a 4 ft. carpenter’s level. Your first step is to follow

the existing directions by positioning the Lift Strut Bracket onto

the spars, so that the center of the Strut Bracket bolt hole is

96.75 inches from the root end of the spar for Model IV and XL

aircraft. For the Speedster, use an initial starting point of

97.75 inches from the root end of the spar. The Lift Strut

Brackets should be temporarily held in place with hose clamps.

Follow existing instructions for temporarily installing both

wings, making sure you DO NOT drill the rear spar bottom

hole, or either top or bottom front spar holes, until a final

dihedral check is made.

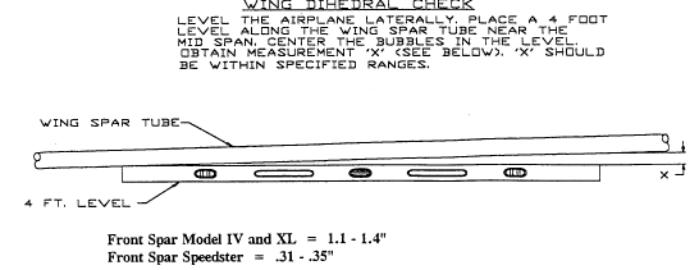

The

final dihedral check is made only after making sure the fuselage

is leveled both laterally and longitudinally. Once the fuselage is

leveled, with the wings, struts and Lift Strut Brackets

temporarily assembled, simply hold your 4 ft. carpenter’s level

up to the bottom of the leading edge spar at a mid span location.

Because of the dihedral, the bubble will not be centered if the

level is held firmly against the spar. Simply lower the “wing

tip” end of the level until the bubble is centered. The

following distance should exist between the “wing tip” end of

the level and the spar:

|

|

You

can further increase dihedral accuracy by also checking the rear

spar. After checking the front spar, simply multiply the value you

measured (let’s say it was 1.1”) by 1.137. In this example,

1.1” x 1.137” =

1.25”, meaning the

top edge of your 4 ft. level should be 1.25”

below the rear

spar.

If

these distances are not present, simply loosen the clamps holding

the Lift Strut Bracket and move the brackets inboard to increase

dihedral, or outboard to decrease dihedral. Once you are satisfied

with overall wing alignment, complete the wing installation, as

indicated in your Builders Manual.

STRUT

FIT

In

some cases, a gremlin called “weld warp” causes carefully

jigged, welded parts to fit incorrectly when installed on an

airframe. This “warping” results from unevenly heated surfaces

acting upon surrounding metal in a fashion which distorts the

intended shape. Fortunately, the flexibility of 4130 steel tubing

permits such warping to be resolved, in many cases, by applying

pressure on the part, to rectify the warped condition. The elevator

to stabilizer fit is often subject to such warpage, and requires the

builder to “nudge” parts until a pleasant fit is obtained.

Recently,

we have seen some wing lift struts exhibit an alignment issue

wherein, after attaching the forward strut to the front spar attach

bracket, the rear strut hangs below the rear spar attach bracket. In

some cases, a good deal of force must be applied to move the rear

strut into place. Can anything be done about this

you bet!

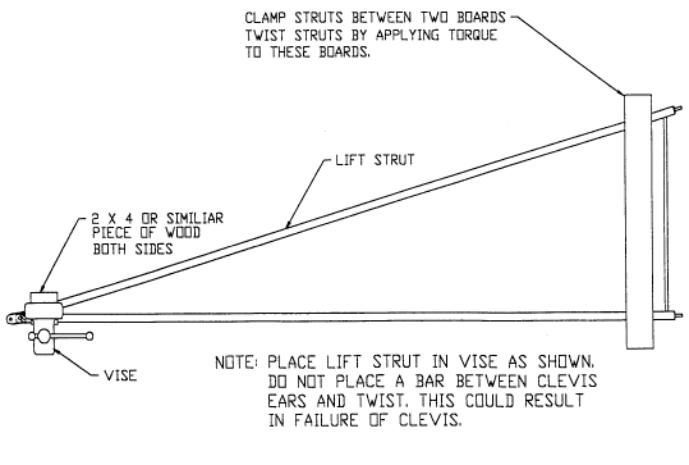

By clamping the “fuselage” end of the strut into a vise (with boards on each side to prevent scoring), a twisting force can be applied to the “wing” end of the struts, thereby correcting the misalignment. The diagram below shows the proper placement of clamps and force. The strut must be nudged past the actual point of adjustment required to allow for the natural spring back. This process may be repeated several times until a tension free fit is secured. Absolutely no harm is caused to the struts, and you will have ensured a custom fit to your specific wing dimensions. Please feel free to contact Builder Support if you have any questions.