SERVICE

LETTER #48

DATE:

August 22, 1995

SUBJECT:

Welded landing gear

APPLICABILITY:

All tail draggers with welded landing gears

COMPLIANCE:

As required

FROM:

SkyStar Aircraft Engineering Department

The

purpose of this service letter is to give you information regarding

the design and proper handling of the welded tube landing gear. It

has been our experience that incorrect handling of the aircraft on

the ground (especially during landing) and poor maintenance have led

to failures in a few of these gears in the field.

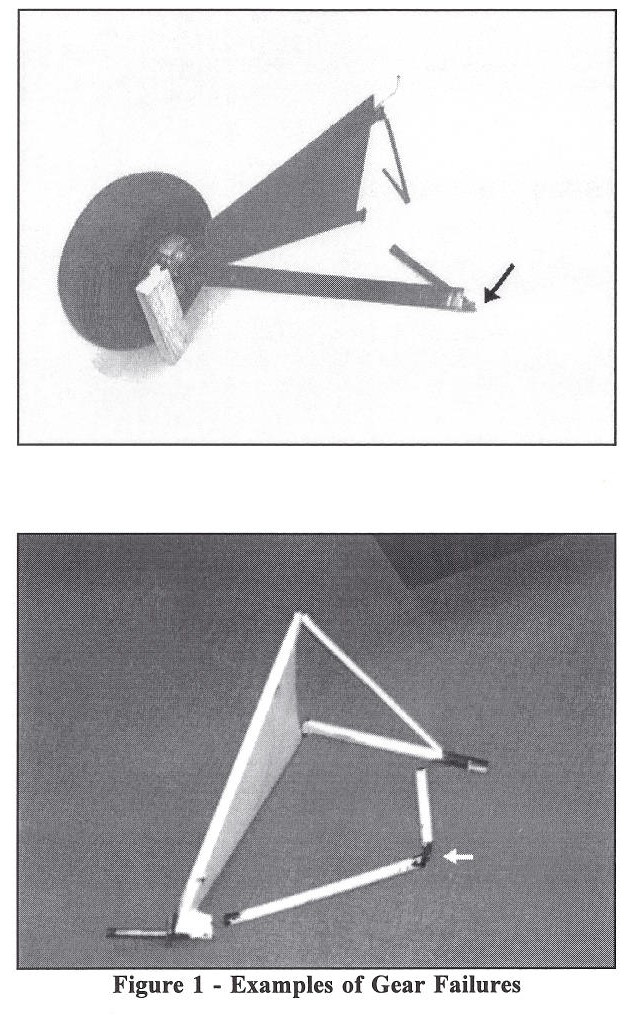

Figure

1 shows two examples of landing gear failures. The top photo shows a

gear which experienced a failure upon landing when the top

horizontal tube failed just outboard of the bungee cords. It is

believed that this particular gear, which had thousands of cycles on

it, began to experience fatigue around the bungee and a small crack

began to form. Moisture may have also been a factor as the fatigue

crack was exposed and susceptible to corrosion.

The

bottom photo is a gear which failed after the pilot landed the

aircraft while still in a crab (not advisable to do in a tail

dragger). As the side loads from the landing were imposed on the

gear, the brace buckled. It is possible that this brace was not

quite straight which would have significantly reduced its load

carrying capabilities. Previous hard (and misaligned) landings may

have also caused the tube to be less effective in withstanding the

imposed side loads. Damage like this may not be uncommon because we

have seen a tendency of new Kitfox™ pilots to try to align the

aircraft with the centerline of the runway on final approach using

the side of the cowl as a reference. The cowl, however, does not

extend straight forward from the side of the fuselage, and using it

as a reference will place the aircraft at an angle of up to 20° to

the runway.

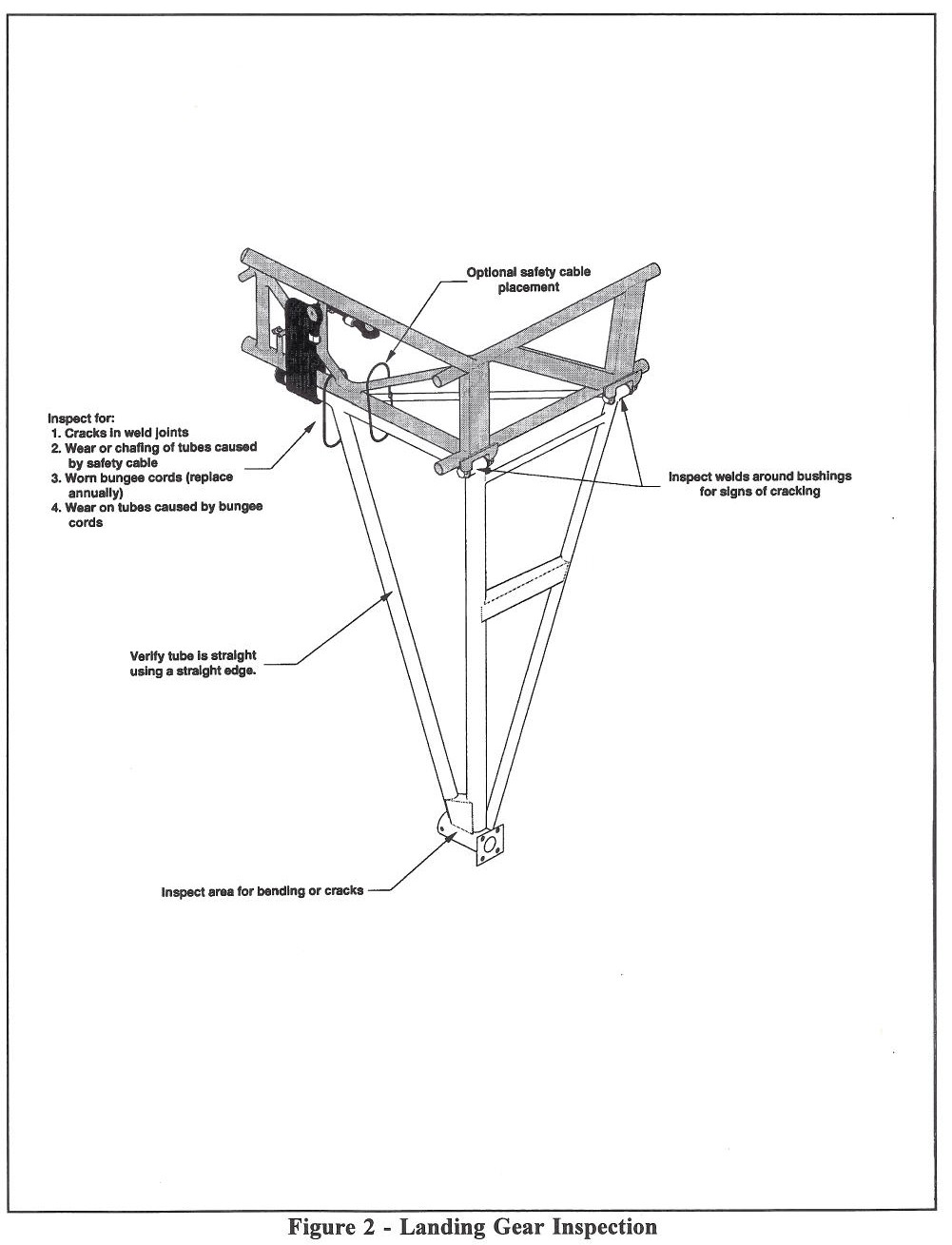

Prior

to your next flight, we strongly recommend that you inspect your

landing gear carefully. Figure 2 gives some general guidelines for

this inspection. Begin by looking at all of the welded joints to

insure there are no signs of fatigue. Next, make certain all

structural members are straight, there are no dents in any members,

and the bungee cords and the safety cable are not wearing or chafing

on the gear members. The condition of the bungee should also be

checked, and it should be replaced annually.

You

should inspect the landing gear for both fatigue and bending during

each pre-flight inspection of the aircraft. Also, try to keep the

landing gear clean. Residue from the engine exhaust may tend to

build up on the gear, which can be corrosive to the gear itself. It

is also much easier to detect potential problems when inspecting a

clean gear.

With

the failure shown in the top photo of Figure 1, it may be seen that

the safety cable would not be effective in this type of failure.

Because of this, you may wish to relocate the safety cable to the

position shown in Figure 2. This would prevent the gear from

collapsing if the structural member were to fail, as well as in the

event of a broken bungee.

Finally,

you may wish to obtain a copy of How To Fly A Kitfox™ by

Edward S. Downs if you haven't already done so and review Chapter

13, Landing. Using the information presented in this chapter should

help you make landings which will reduce the likelihood of landing

gear problems. For those builders who are still working toward your

first flight in your aircraft, we encourage you to spend some time

becoming proficient in tailwheel aircraft, especially a Kitfox™,

if you aren't already prior to your first flight. SkyStar offers a

familiarization flight training program here at the factory which

will allow you to become comfortable with the aircraft. Call our

Customer Service department for more information about this program.