November

11, 1992

SERVICE

BULLETIN #26

SUBJECT:

LIFT STRUT ATTACH BRACKET TO FUSELAGE

TO:

Kitfox™ AIRCRAFT MANUFACTURED BETWEEN Sept. 1.1992 AND Oct.

16.1992

FROM:

SKYSTAR AIRCRAFT CORPORATION.

It

has come to our attention that some lift struts, shipped between Sept. 1

and Oct. 16, 1992, have fuselage mounting brackets that may have an

improper gap between tabs, thus allowing the lift strut to fit too loose

on the fuselage tab. This excess play between the fuselage mounting tab

and the lift strut attach bracket, does not allow the castle nut to be

secured on the AN6-11 bolt with a full safety pin hole showing on the

bolt. There should be virtually no play between the fuselage mounting

tab and the lift strut bracket. The temptation would be to over torque

the AN6-11 bolt, to lessen the gap, but this would result in permanent

damage to the bolt.

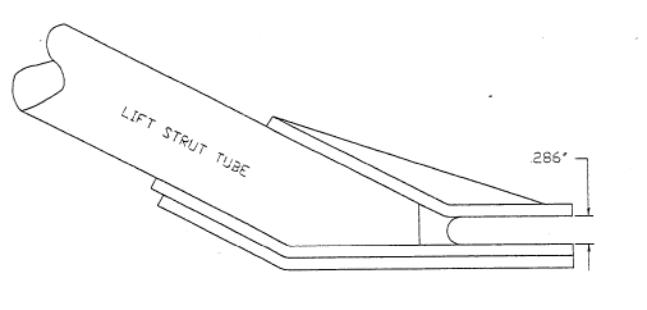

The

appropriate lift strut bracket gap, prior to paint or powder coating,

should be 0.286”. Measure the thickness of the lift strut mounting tab

on the fuselage and compare it to the distance between the flanges of

the lift strut bracket. Typically, the lift strut bracket gap should be

no more than 0.01” wider than the thickness of the fuselage tab. There

should be little, if any, play between the lift strut and fuselage when

installed correctly.

RECOMMENDATION:

Using

the typical, hardware store variety 3/8” fine thread cap bolt,

matching washer and nut, as a torquing lever, tighten the bolt and nut

down until the gap on the lift strut bracket is approximately 0.02”

less than the required distance, allowing for some “spring back”.

This should close the gap to the required distance and allow adequate

securement of the castle nut on the bolt. You may wish to repeat this

procedure in small increments until a good fit is established.

As

a safety factor, please discard these over torque bolts and nuts. These

bolts are not A/C quality. If you use AN, MS or NAS bolts for this

adjustment, please discard them also because the adjustment will require

a higher torque value than allowed for this hardware.

If

you any have questions about this bulletin or procedure, please call our

Technical Department, at (208) 466-1711 or by Fax; (208) 466-7194.